Archive for February, 2014

When It Comes To Hammer Felts We Follow The Sheep

Posted by Britannia Piano Auctions in Education on February 5, 2014

Felt is one element of the mechanics in a piano, but is it a small element or a big one…

The finest hammer felts produced for pianos are made from virgin wool. It is classed as virgin wool when it comes from the very first shearing of a sheep.

Virgin wool contains the longest fibre and greatest lanolin content, it can be removed from each sheep only once. This is the reason that it is very rare and very expensive.

Each shearing that takes place post the ‘virgin shearing’ produces a wool that is drier and more brittle, this is due to the Lanolin content being lower.

| What Is Lanolin

Lanolin also called wool wax or wool grease is a yellow waxy substance secreted by the sebaceous glands of wool-bearing animals. Most lanolin used by humans comes from domestic sheep breeds that are raised specifically for their wool. Lanolin is a wax. Historically, many pharmacopoeias have referred to lanolin as wool fat; however, as lanolin lacks glycerides, it is not a true fat. Certain breeds of sheep produce large amounts of lanolin, the extraction can be performed by squeezing the sheep’s harvested wool between rollers. Most or all of the lanolin is removed from wool when it is processed into textiles, such as yarn or felt. |

Hammer felt is categorised by weight in pounds; this is measured by weighing a square yard of the primed felt. So when you read about 18 pound hammers you will know that it refers to the weight of the square yard it was cut from rather than the weight of each individual hammer.

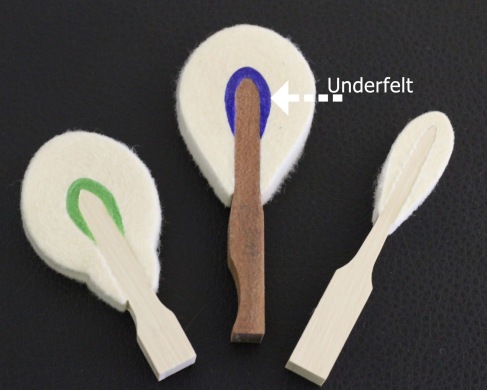

In the construction of a hammer there is a wooden base, the felt is mounted onto the wooden hammer under great pressure. Tension must exist in the hammer felt to offer a resilient bounce off the string after it has been struck. Too much tension or not enough is a negative and can stifle the tone production.

Frequently manufactures use a thin layer of colored felt that they attach to the wooden hammerhead before attaching the final white/cream coloured felt that touches the string. This felt is called the ‘under felt’

The theory behind ‘under felting’ is one that piano makers, sellers and players are still divided on. Some believe that it adds to the overall experience whilst others believe it is a gimmick and the process of under felting is not necessary.

You can see how the felt is added to the hammer in this picture. The felt is glued down and often stapled.

All hammer felts have to be glued to stabilise the felt to the hammer, in most cases they are glued and stapled

So now at your next ‘piano party’ you can spread your knowledge about piano hammers!

Did you find this blog interesting? Then subscribe to us here and on Facebook to see all our informative blogs & short articles of interest as well as detailed previews of auction lots.

The UK’s Central Piano Auction House

www.britanniapianoauctions.com

info@britanniapianoauctions.com

0161 977 0075

Auction, auctions, bargain, Bechstein, Birmingham, Bristol, Britannia, Buy, Edinburgh, Education, England, Hall, house, Keyboard, London, Ltd, Manchester, Music, North west, Piano, RAM, RCM, RNCM, sell, Selling, Shopping, Steinway, uk, upright, Yamaha

-

You are currently browsing the archives for February, 2014

-

-

- Art Case (1)

- Auction Insights (31)

- Auctions (24)

- Bebbington (1)

- Buying (15)

- Education (12)

- History (2)

- John (1)

- Liza Fuchsova (1)

- Manchester (4)

- Martin Roscoe (1)

- Model B (1)

- Music (4)

- North West (4)

- Ogden (1)

- Paul Hamburger (1)

- Peter Katin (1)

- Pianos (22)

- Provenance (1)

- RADA (3)

- RNCM (3)

- RSM (3)

- Selling (7)

- Steven Kovacevizc (1)

- Uncategorized (50)

Archives

- March 2017 (1)

- August 2016 (1)

- July 2016 (1)

- June 2016 (5)

- April 2016 (1)

- March 2016 (7)

- December 2015 (1)

- October 2015 (3)

- September 2015 (1)

- July 2015 (2)

- June 2015 (2)

- May 2015 (1)

- April 2015 (3)

- March 2015 (1)

- February 2015 (1)

- January 2015 (2)

- December 2014 (5)

- November 2014 (2)

- October 2014 (4)

- September 2014 (3)

- July 2014 (2)

- June 2014 (10)

- May 2014 (2)

- April 2014 (1)

- March 2014 (7)

- February 2014 (1)

- January 2014 (3)

- December 2013 (3)

- November 2013 (4)

- October 2013 (4)

- September 2013 (3)

- August 2013 (6)

- July 2013 (1)

- June 2013 (1)